Bardac offers a complete range of regenerative and non-regenerative DC drives,

single and three phase input, with wide ranging current and voltage ratings.

All drives are compact with small foot prints, making them ideal for retrofits.

Our digital drives are easily connectable via USB and Ethernet.

Most drives, fractional through 2000HP+ are in stock and ready to ship same day!

Sales and after sales support is provided by experienced application engineers.

To request a quote, please call or use the online quote request form.

PL Series

Digital 3-Phase Drives up to 2000HP+

High performance, powerful application blocks with a small footprint.

6-pulse or 12-pulse, 230, 460, 600 or 690 VAC configurations.

K-Series

Single Phase Drives up to 2HP

Enclosed, DIN rail mounting drives in elegant compact packages.

Suitable for both stand alone and systems applications.

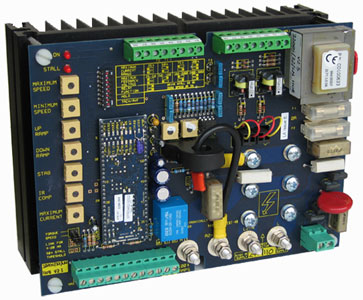

Systems and Retrofit Drives

Single Phase Input up to 10HP

Isolated and non isolated, regenerative and non regenerative.

Multiple voltage inputs; 120, 230, 380, 415 and 460V voltage.

Multiple current ratings; fractional to 48A. Extensive I/O.

Linear Amplifier DC Servo Drives

Single Phase Input up to 10HP

These drives are designed for small, high performance position and

speed control applications such as robotics, mechanical handling,

automated assembly, packaging processes, machine tool axis, etc.

SL Series

Analog DC Drives up to 200HP

Small footprint. These drives are available for either 230 or 460 configurations.Contact

Bardac Corporation

Address: 40 Log Canoe Circle

Stevensville, MD 21666

Phone: (410) 604-3400

Toll Free: 1-888-667-7333

(1-888-ON SPEED)

Fax: 410-604-3500

email: info@bardac.com

For emergency after hours phone support call: (410) 604-3535 (payable at time of service with a credit card)

Address: 40 Log Canoe Circle

Stevensville, MD 21666

Phone: (410) 604-3400

Toll Free: 1-888-667-7333

(1-888-ON SPEED)

Fax: 410-604-3500

email: info@bardac.com

For emergency after hours phone support call: (410) 604-3535 (payable at time of service with a credit card)