drive.web

WINDERS & UNWINDERS

smarty

automation controllers use thedrive.web

distributed control technology to bring easy, cost-effective intelligence to high performance drive systems.smarty apps

are pre-configured generic packages for common applications:smarty

OPTION-1101, Open Loop Constant Tension Center Windersmarty

OPTION-1102, Closed Loop Dancer Controlled Center Windersmarty

OPTION-1103, Closed Loop Load Cell Controlled Center Windersmarty

OPTION-1104, Closed Loop Slip Core Winder

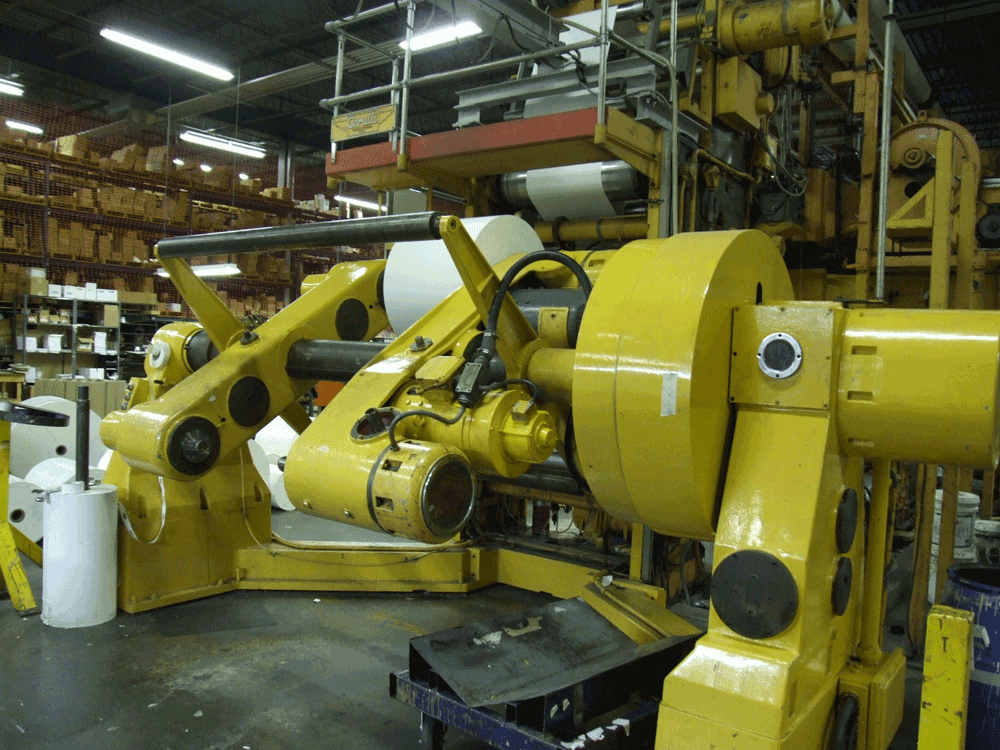

Printing Press, Precision Tension Winder

Standard Features:

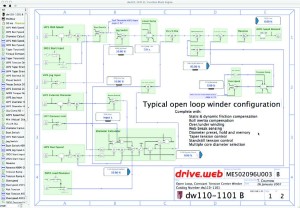

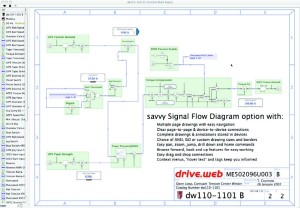

- Fully editable configurations and drawings

- Drive Interface either serial port or analog

- Process control & winder function block libraries

- Web break sensing

- Diameter calculation, memory, preset and hold

- Linear or hyperbolic taper tension

- Friction, inertia & torque compensation

- Multiple core presets

- Integral reset

- Adaptive control for high speed systems

- Standstill tension mode

- Jog/run/slack take up modes

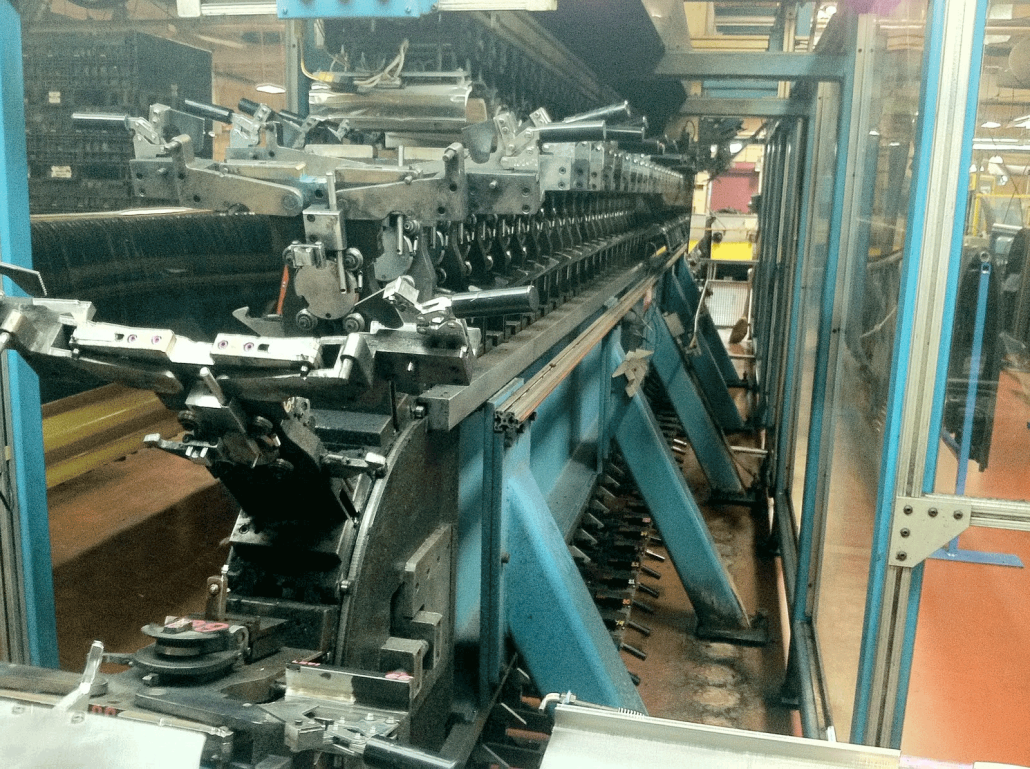

- Turret indexing mode

- Anti-reverse clamps

- Core speed matching

Optional Features:

smarty OPTION-1101

Open Loop Center Winder

smarty OPTION-1101 | |

Open Loop Center Winder | |

| Special features include:

drive.web apps are very easy to interface to most line and winder drives, operator stations and PLCs over Ethernet, RS485 serial communications or via analog and logic wired connections. |

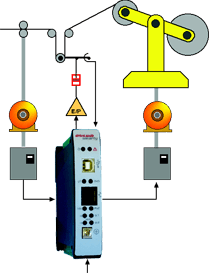

smarty OPTION-1102

Dancer Controlled Center Winder

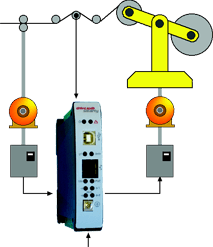

smarty OPTION-1103

Loadcell Controlled Center Winder

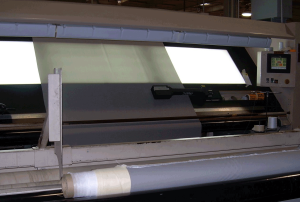

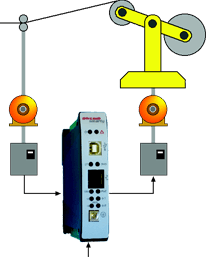

High Speed Printing Press Infeed Turret Unwinder

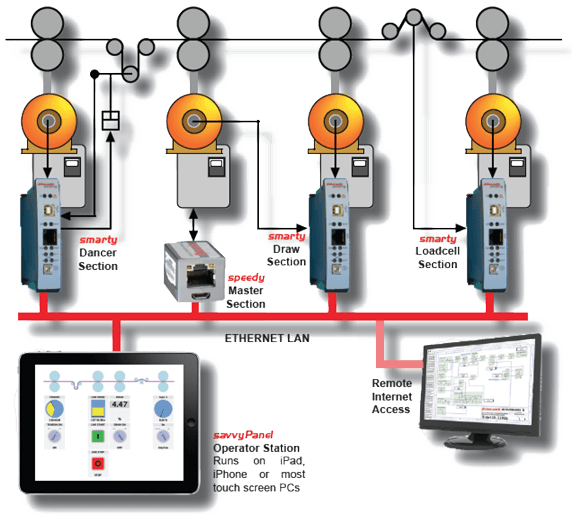

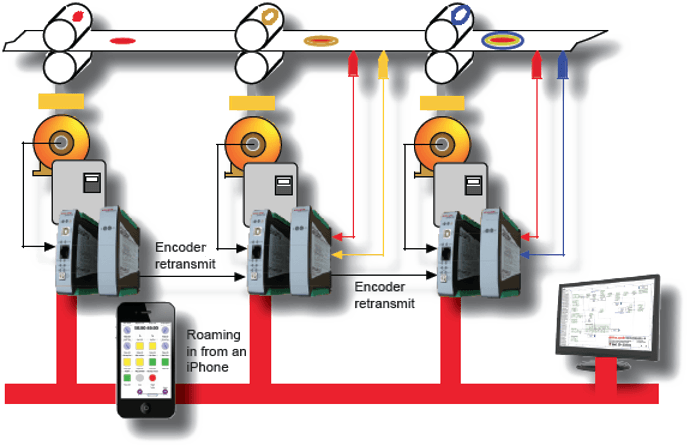

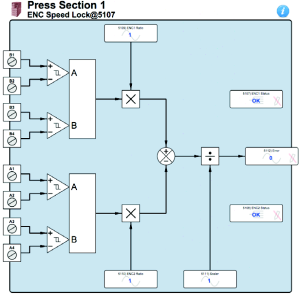

OPTION-1106 PROCESS LINE COORDINATION

Standard function blocks used in combinations ofsmarty's

andspeedy's

can be easily configured to provide line drive coordination in systems of any size or complexity.- Functions such as linear, S and hyperbolic ramps are used to provide master references.

- Programmable logic and switch functions are used to provide line run, line jog, local jog, interlocks, etc.

- PIDs, profilers, registration, indexing, phase lock and arithmetic blocks provide precise section control.

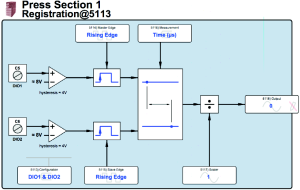

OPTION-1109 REGISTRATION

& ELECTRONIC LINE SHAFT

The Registration & Electronic Line Shaft package is designed for applications such as print registration, synchronized component

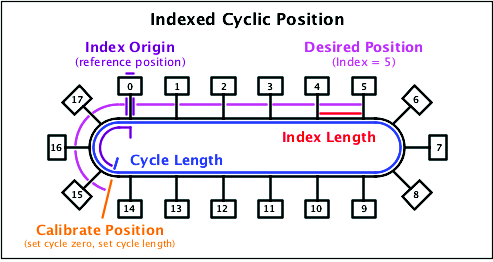

handling, position control, cut-to-length, etc., where precision drive coordination and spindle orientation are required.OPTION-1117 INDEXING & CYCLIC POSITIONING

The optional Encoder Function Block Library available in smarty includes a set of engineered function blocks for use in precision positioning applications such as packaging machines, machine center tool loaders, inventory carousels, stackers, etc.Key Features:

- Auto origin checking

- Auto index calculation

- Auto calculation of shortest move from point to point

- 64-bit encoder counts

Machine Center, Transfer Line

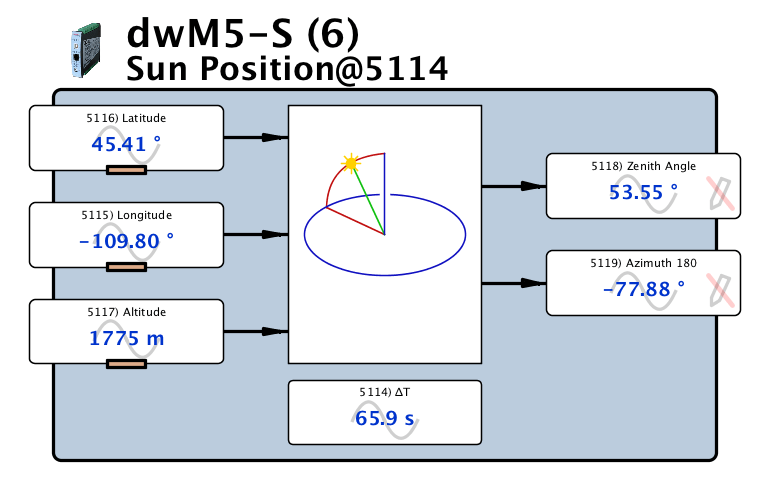

OPTION-1118 SUN POSITION CALCULATOR

The Solar Function Block Library provides precise calculation of the sun zenith and azimuth angles in solar energy systems. It can be synchronized with the SNTP server time and date and include a ∂T input parameter to compensate for the difference between UTC and Terrestrial Time for precise positioning of solar concentrators.Key Features:

- Set up for any latitude, longitude and altitude

- Fast calculation for use in mobile systems

- SNTP synchronization support

- Terrestrial Time correction input