Peer-to-Peer, Distributed Control

Its Importance In Modern Plant Automation

The concept of distributed control has been around for several decades, but the term has often been co-opted to describe systems in which many PLCs or process controllers have been used in a server/client configuration. However, such typically hierarchical connections do not provide the flexibility and versatility of devices connected in a peer-to-peer environment, where parallel processing between devices enables unrestricted connectivity and almost unlimited expandability.

Peer-to-peer connectivity is much more complex than server/client topologies and requires a sophisticated operating system to ensure the deterministic behavior essential in reliable control systems. However, as microprocessors have become more powerful and less expensive, the idea has become both feasible and viable.

Peer-to-peer connectivity is much more complex than server/client topologies and requires a sophisticated operating system to ensure the deterministic behavior essential in reliable control systems. However, as microprocessors have become more powerful and less expensive, the idea has become both feasible and viable.

As we enter a new era of plant automation, smart devices and sensors require the ability to talk to other intelligent entities, human and inanimate, to carry out their jobs more efficiently, and this is where the conventional PLC, server/client topology introduces a road block. Unless the required communications connection has been pre-programmed into the PLC, the poor lowly slave device is trapped and cannot tell the master what’s going on!

The unique Bardac drive.web distributed control technology provides a peer-to-peer environment in which any device can communicate directly with any other device. Data transmission between devices is therefore both unimpeded and inherently faster. Even though the individual devices run asynchronously, the operating system ensures both stable system wide program thread control and precise real-time data using smart time stamping. AC drives, DC drives, programmable controllers, i/o controllers, etc., are all Internet accessible and incorporate a full featured programmable control capability, so as your system gets bigger, each extra component adds more parallel processing capacity and you never run out of steam!

The unique Bardac drive.web distributed control technology provides a peer-to-peer environment in which any device can communicate directly with any other device. Data transmission between devices is therefore both unimpeded and inherently faster. Even though the individual devices run asynchronously, the operating system ensures both stable system wide program thread control and precise real-time data using smart time stamping. AC drives, DC drives, programmable controllers, i/o controllers, etc., are all Internet accessible and incorporate a full featured programmable control capability, so as your system gets bigger, each extra component adds more parallel processing capacity and you never run out of steam!

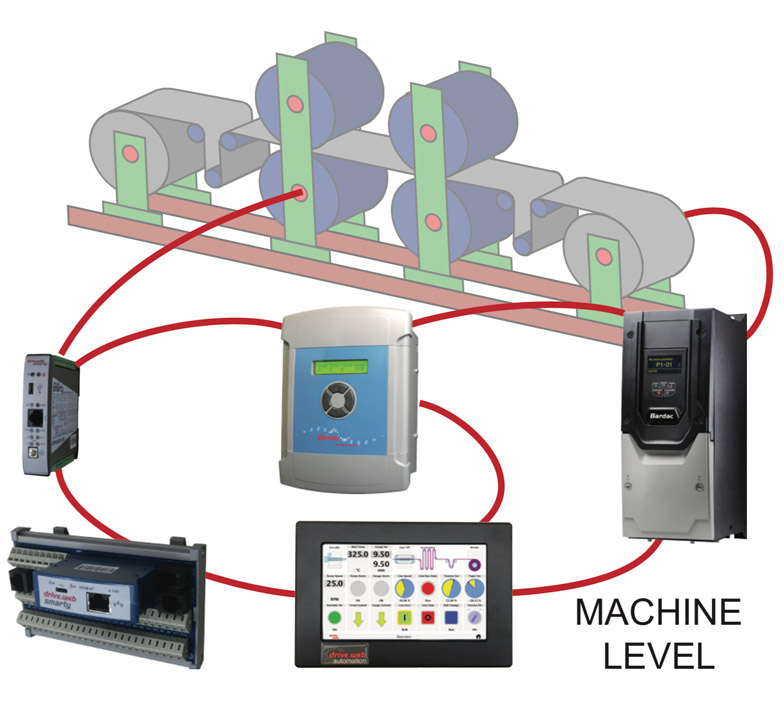

At the basic machine level all components are connected by an Ethernet LAN, and the whole system can be accessed either via the LAN or any of the device USB ports. savvyPanel HMI configurations reside in the devices for easy iOS or Android mobile access.

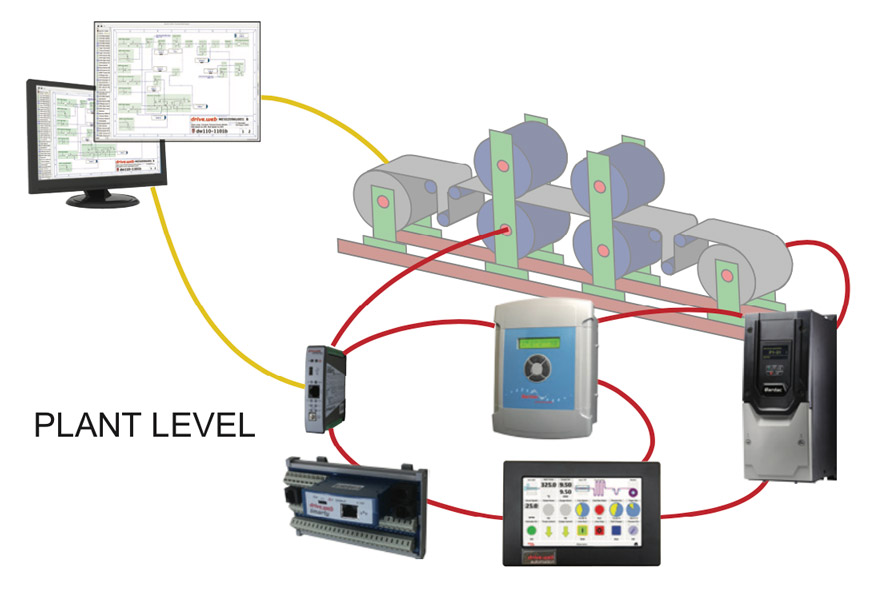

Local engineering, production and SCADA access can easily be interfaced to the machine system and complete, safe access provided to remote enterprise locations via a secure VPN connection. The important thing about the drive.web distributed control concept is that any device in the entire enterprise can talk to any other device (with security access).

Two other interesting drive.web products are the speedy controller and the savvy software.

The speedy is a minute processor  (less than half the size of your thumb) that easily embeds into most third party drives to provide both onboard programmable control functions and the peer-to-peer, distributed control capability, thereby eliminating the potentially isolated nature of the drive.web technology.

(less than half the size of your thumb) that easily embeds into most third party drives to provide both onboard programmable control functions and the peer-to-peer, distributed control capability, thereby eliminating the potentially isolated nature of the drive.web technology.

The savvy platform independent tools provide seamless, system wide programming and control. drive.web’s versatility, ease of use and inclusive nature will ensure its ready acceptance into the Industrial Internet of Things arena.